Plating of various metals onto titanium is a challenging process, however it can

significantly

enhance some properties of the substrate, allowing its use in an even wider variety of

applications.

Depending on the top coating used, plating process may lead to increase of the corrosion

resistance,

and the resistance to surface fatigue. Additionally, properties may be provided such as

anti-galling, fretting, self-lubrication, solderability, heat reflection and adjustment of

the

conductivity.

Although potential application of coatings in titanium made objects is beneficial, at the

same time

is a very challenging process due to the fact that titanium is a very active metal.

The Pla3DTi will works towards surpassing these barriers by developing a plating process for

applying nickel coatings in 3D printed Ti alloy based objects. The general objectives of the

project are:

To develop a suitable pretreatment process for the application of coatings in the surface of 3D printed objects.

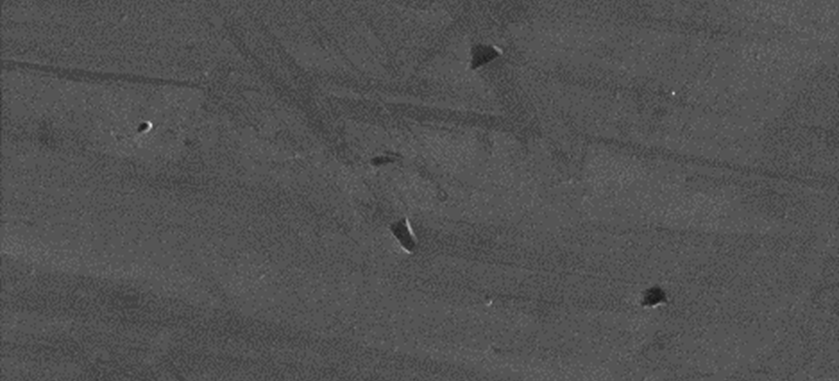

To investigate the structure and morphology of the 3D printed objects and how this affects the adhesion of the coatings.

To apply various Ni-based coatings on the 3D printed objects.

BB1/ MWAM (AIMEN) BB3/ Testing, (PoliMi), Innovation Management (AXIA).